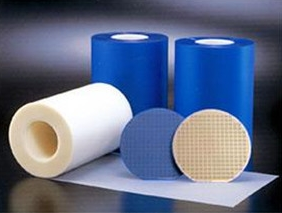

A dicing tape is used for fixing a work piece during the dicing process in the manufacturing of semiconductors, electronic and optical components.

With greater diversity and higher quality in chips , dicing tapes also require advanced technology.

Roll types , dicing , reels and shapes etc. are important for dicing tapes selections.

NEXTECK provides customized dicing tapes to meet all kinds of requirements.

Features

| Recommended works | Part Number | Base Film | Color | Thickness | Adhesion Thickness | Adhesive Strength | Probe Tack | Feature |

| (μΩ) | (μΩ) | (N/20mm) | (N/20mm2) | |||||

| Si | F-90MW | PO | MW | 90 | 10 | 1 | 1 | PVC-free type |

| GaAs | T-80MW | PVC | 80 | 0.8 | 0.7 | Excellent | ||

| Other | T-80HW | 1.7 | 1 | Temporal | ||||

| Semiconductor | T-120HW | 120 | 1.7 | 1 | Stability | |||

| Thick Workpiece | 20GE-200 | LB | 200 | 2.7 | 2.9 | For thick | ||

| workpiece |

Central values listed rather than guarantee values.

Static-free

Colors : milk white, light blue, transparency .

Stripping film thickness excluded

Dicing Tape - UV Series

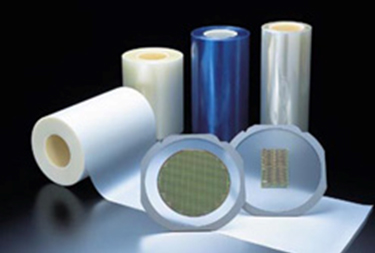

A dicing tape is used for fixing a work piece during the dicing process in the manufacturing of semiconductors, electronic and optical components.

With greater diversity and higher quality in chips, dicing tapes also require advanced technology.

Dicing tapes of NEXTECK are widely used in a variety of applications including slicing , single EMC encapsulation substrate , drive IC , LTCC substrate , silicon chip , ceramics , glass, and optical lens .

UV series dicing types have ultra high crystallized ability by adhesion and ultraviolet irradiation , easy to be peeled , without remains and anti-static. We provide whole roll as well as customized shapes.

NEXTECK provides customized tapes to meet all kinds of requirements.

Models

UDV - 80J / UDV - 100J / UHP - 110B

UHP - 0805MC / UHP - 1005M3

UHP - 110M3 / UHP - 1025M3

UHP - 1510M3 / UHP - 1525M3

USP - 1515M4 / USP - 1515MG

UDT - 1025MC / UDT - 1325D

UDT - 1915MC

Merits

Excellent control to back-side chipping and chip fly-off

Excellent over-time stability (T Series)

Excellent adhesiveness

High performance to EMCs (Epoxy Mold Compounds) and other types of difficult-to-adhere work- pieces

Specifications

| Recommended WorkⅠ | Si GaAs Other Semiconductor | |||||

| Part Number | UDV-80J | UDV-100J | UHP-110B | UHP-0805MC | UHP-1005M3 | UHP-110M3 |

| Base Film | PVC | PO | ||||

| Color | T | MW | ||||

| Thickness(μΩ) | 80 | 100 | 110 | 85 | 105 | 110 |

| Adhesion Thickness (μΩ) | 10 | 5 | 10 | |||

| Adhesive Strength (N/20mm) | 3.8(0.2) | 3.8(0.2) | 2.9(0.2) | 5.0(0.2) | 5.0(0.2) | 7.6(0.2) |

| Probe Tack (N/20mm2) | 2.1(0.05) | 2.1(0.05) | 2.7(0.05) | 1.7(0.05) | 2.7(0.05) | 3.9(0.05) |

| Characteristic | Easy pickup | For less chipping | For small size chips | |||

| Recommended Work Ⅱ | Package | |||||

| Part Number | UHP-1025M3 | UHP-1510M3 | UHP-1525M3 | USP-1515M4 | USP-1515MG | |

| Base Film | PO | |||||

| Color | MW | |||||

| Thickness(μΩ) | 125 | 160 | 175 | 165 | ||

| Adhesion Thickness (μΩ) | 25 | 10 | 25 | 15 | ||

| Adhesive Strength (N/20mm) | 12.0(0.2) | 6.5(0.2) | 13.5(0.2) | 14.5(0.2) | 15.0(0.2) | |

| Probe Tack (N/20mm2) | 5.5(0.05) | 4.2(0.05) | 5.6(0.05) | 6.2(0.05) | 5.9(0.05) | |

| Characteristic | For encapsulated workpiece For less backside burrs For less glue scratch-up on the chip side walls For less against residue onto a making area | |||||

| Recommended Work Ⅲ | Glass Crystal | |||||

| Part Number | UDT-1025MC | UDT-1325D | UDT-1915MC | |||

| Base Film | PET | |||||

| Color | T | |||||

| Thickness(μΩ) | 125 | 155 | 203 | |||

| Adhesion Thickness (μΩ) | 25 | 15 | ||||

| Adhesive Strength (N/20mm) | 30.0(0.2) | 20.4(0.2) | 20.3(0.2) | |||

| Probe Tack (N/20mm2) | 7.5(0.05) | 6.7(0.05) | 5.9(0.05) | |||

| Characteristic | For less backside cracking | For encapsulated workpiece | For less backside cracking | |||

The values in the ( ) stands for the adhesive strength after ultraviolet irradiation .

Values above are central values rather than guarantee vuales .

Static free

Color : MW (mike white ) , T (transparent)

UV exposure condition : Integrating brightness=150mJ above / cm2

Product situation is subject to the UV explosure conditions.

Stripping film thickness excluded

Each items of NEXTECK win years of accumulation and trust. Products used for semiconductors and electronic parts are very completed and with varied shaping methods,excellent forming property and size precision.