Features

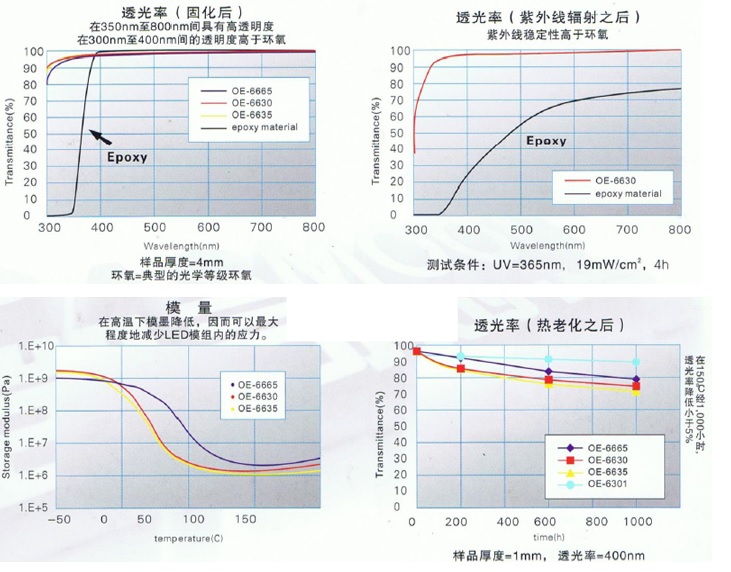

• High optical transparency

• Excellent UV resistance

• Excellent thermal stability

• Low moisture up-take

• Low ionic content

Benefits

• Well-suited for IR, visible or UV

optical applications

• Lead-free solder reflow temperatures

• Flexibility in manufacturing

• Good adhesion to various lead frames

High Refractive Index(RI = 1.54)

| Product Name | OE6500 | OE6551 | OE6630 | EG6635 | OE6636 | OE6650 | OE6631 | OE6662 | OE6450 |

| Characteristic | Long hours to stream,High optical transparency,High RI | Upgraded version of OE6550 ,strong adhension | High refractive index, lower viscosity | Superior viscosity ,stron adhension,high transparency | High viscosity, strong adhension | Strong adhension, high viscosity,higher solidity | Strong adhension, high viscosity,lower solidity | Strong adhension,high solidity, low Low permeability | Cryogenic soild,high refractive index, jelly gel |

| ,adjustable ratio | ,high transparency | ||||||||

| Applied Range | Mixed fluorescent powder | Mixed fluorescent powder | SMD LED encapsulation,Molding | SMD LED(SIDE VIEW LED encapsulation | SMD LED encapsulation, TV LCM type LED encapsulation | SMD LED encapsulation, TV LCM type LED encapsulation | SMD LED , TV LCM type LED encapsulation | SMD LED encapsulation,Outdoor LED type products | HP LED lens filling |

| Mixing Ratio | 1:01 | 1:02 | 1:04 | 1:03 | 1:02 | 1:03 | 1:02 | 1:04 | 1:01 |

| Thermocuring Condtion | 150 ℃ 1h | 150 ℃ 1h | 80 ℃ 1h+ 150 ℃ 3h | 80 ℃ 1h+ 150 ℃ 3h | 80 ℃ 1h+ 150 ℃ 3h | 80 ℃ 1h+ 150 ℃ 3h | 80 ℃ 1h+ 150 ℃ 3h | 80 ℃ 1h+ 150 ℃ 3h | 100 ℃ 1h |

| Before Cure | |||||||||

| Color | Transparent | Transparent | Transparent | Transparent | Transparent | Transparent | Transparent | Transparent | Transparent |

| Viscosity 25℃ (mPa.s) | 25000/1000 (A/B) MIXED:4000 | 4600/5200 (A/B) MIXED:4400 | 2100/2300 (A/B) MIXED:2200 | 32500/2810 (A/B) MIXED:4870 | 13400/5225 (A/B) MIXED:7650 | 13000/4800 (A/B) MIXED:6000 | 5900/13500 (A/B) MIXED:7150 | 12000/2900 (A/B) MIXED:4000 | 2900/1400 (A/B) MIXED:1900 |

| Density (g/cm3) | 1.16/1.12(A/B) | ||||||||

| After Cure | Elastomer | Elastomer | Silicone | Silicone | Silicone | Silicone | Elastomer | Silicone | Gel |

| Shore | A62 | A53 | D35 | D33 | D34 | D52 | A69 | D66 | |

| Refractive Index 633m | 1.54 | 1.54 | 1.53 | 1.536 | 1.54 | 1.54 | 1.54 | 1.54 | 1.544 |

| Light Transmittance | 100 | 100 | >95 | >95 | 100 | 100 | 100 | 100 | >95 |

| 450mm(%) | |||||||||

| Coefficient of Linear Expansion(1/k) | - | - | - | - | - | - | - | - | - |

| Tensile Strength | - | - | - | - | 3.8 | 7.3 | - | - | - |

| (Mpa) | |||||||||

| Na+ Content(ppm) | 0.1 | - | - | - | 0.1 | 0.1 | - | - | - |

| K+ Content(ppm) | 0.2 | - | - | - | 0.2 | 0.2 | - | - | - |

| Cl+ Content(ppm) | 1 | - | - | - | 0.5 | 0.5 | - | - | - |

| Volume Resistivity(Ω/cm) | - | - | - | - | - | - | - | - | - |

| Dielectric strength (KV/mm) | - | - | - | - | - | - | - | - | - |

※ Light transmittance of sample with 1mm in thickness.

Common refractive index series(RI = 1.41)

| Model No. | OE6336 | EG6301 | OE6351 | OE6370HF | OE6370M | OE6250 |

| Property | Longer hours on stream, high transparency,hard elastomer | Medium viscosity, | Lower solidity,strong adhension | Higher viscosity,strong adhension,curing rate fast | Medium viscosity,strong adhension,improving surface viscosity | low-temperature setting, |

| high transparency, strong adhension | low viscosity,jelly gel | |||||

| Application | SMD LED,Molding | SMD LED | SMD LED,Molding | Molding ( Develop materials with automatic molding equipment ) | SMD LED | HP LED lens filling |

| Mixing Ratio | 1:01 | 1:01 | 1:01 | 1:01 | 1:01 | 1:01 |

| Thermocuring Condition | 80 ℃ 1h+150 ℃ 3h | 80 ℃ 1h+150 ℃ 3h | 80 ℃ 1h+150 ℃ 3h | 80 ℃ 1h+150 ℃ 3h | 80 ℃ 1h+150 ℃ 3h | 60 ℃ 30mins |

| Before Cure | ||||||

| Color | Transparant | Transparant | Transparant | Transparant | Transparant | Transparant |

| Viscosity 25℃( mPa.s ) | 900/2100(A/B) MIXED:1500 | 3200/4000(A/B) MIXED:3500 | 2700/2200(A/B) MIXED:6110 | 6060/5950(A/B) MIXED:6110 | 8800/1900(A/B) MIXED:3800 | 450/450(A/B) MIXED:450 |

| After Cure | Elastomer | Elastomer | Elastomer | Elastomer | Elastomer | Gel |

| Density( g/cm3 ) | 1.03 | 1.03 | 1.03 | 1.03 | - | 1.03 |

| Shore | A65 | A75 | A50 | A71 | A71 | - |

| Extensibility ( % ) | 70 | 75 | 80 | 83 | - | - |

| Refractive Index,633mm | 1.41 | 1.41 | 1.41 | 1.41 | 1.41 | 1.41 |

| Light Transmittance 450mm ( % ) | >95 | 97 | 99 | 99 | 100 | 100 |

| Coefficient of Linear Expansion ( 1/k ) | 2.50E-04 | 2.50E-04 | - | - | - | - |

| Tensile Strength(Mpa) | 7 | 9 | - | - | - | - |

| Na+ Content (ppm) | <0.1 | <0.1 | <0.1 | <0.1 | <0.1 | <0.1 |

| K+ Content(ppm) | <0.2 | <0.2 | <0.2 | <0.2 | <0.2 | <0.2 |

| Cl+ Content (ppm) | <1 | <1 | <1 | <1 | <0.5 | <1 |

| Volume Resistivity(Ω/cm) | 3.00E+1.5 | 7.00E+1.5 | - | - | - | - |

| Dielectric strength (KV/mm) | 25 | 28 | 25 | 28 | - | 25 |

※ Light transmittance of sample with 1mm in thickness.

NEXTECK provides completed evaporation materials for resistances and electron beams .The materials can be manufactured to variety shapes and specifications , including strip, wire, rod, pellet and pieces etc. NEXTECK not only provides standard metal evaporation materials, but also make composite materials, hot pressed ceramics for alloys and vaccum casting materials.