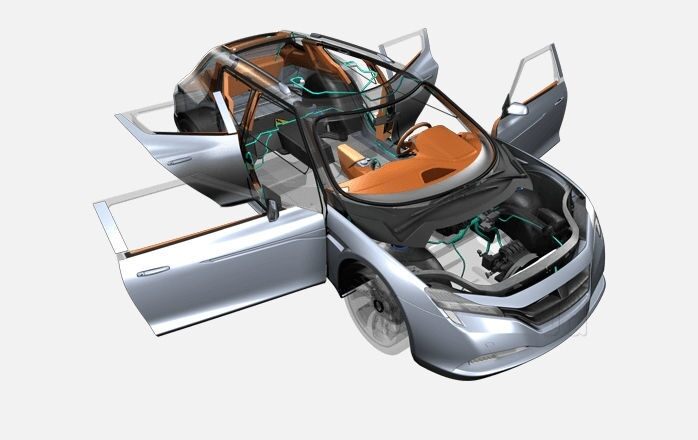

Copper is a multi-purpose material whose properties have made it a key component in vehicles since the dawn of the car industry with the Model T Ford in 1916. Today, copper plays a critical role in cars for functionality, efficiency, comfort and safety. Even the most basic model contains some 1 km of wiring, mostly used to carry data, send control signals and supply electrical power. The total weight of copper in a vehicle ranges from 15 kilos for a small car to 28 kilos for a luxury car. Nexteck Technology provides various copper alloys and copper related electrothermal alloys for automotive industries.

Motors, alternators, actuators and electrical chokes, and the wiring harness itself, all depend on reliable high conductivity. More copper will be needed as automotive electrical developments increase awareness, safety and automation. Electrified railways, trams and light railways are powered through overhead copper alloy contact wires. High quality brass has the long-life springiness and resistance to corrosion that makes it ideal for electrical connections.

Car designers and manufacturers are constantly developing electronic applications which rely on the electrical conductivity of copper:

Sensors for the automotive industry make up around a third of the global sensor market. With a true sensory system for the car, the sensors allow, for example, dangers on the road to be detected, braking to be adapted, the temperature inside to be controlled, self-diagnosis tests to be run on the vehicle. They make use of copper – notably, in the coils and cables.

ABS or Antilock Braking System was one of the first ‘smart’ technologies, designed to make driving safer by adjusting the braking depending on the grip. Since then, a whole series of innovations have expanded the solutions available with regard to braking and road grip, including EBD (Electronic Brake-force Distribution) for improved distribution of the brake force or ESC (Electronic Stability Control) that enhances the stability of the car.

More than a mere speed regulator, the AICC (Autonomous Intelligent Cruise Control) allows a speed previously set by the driver to be maintained without having to keep the foot on the accelerator. A technology available on top of automatic transmission, the AICC monitors the speed of the vehicle in front and changes its own speed accordingly, while keeping a good safety distance.

The car is now much more than a pure means of transportation. It is designed to be comfortable and equipped with work and leisure spaces. Thanks to an ever increasing number of applications that exploit copper’s benefits, the seats are able to remember and automatically adjust to the passenger, thanks to an array of small motors. Automatic temperature controls keep the interior at a comfortable level and telecommunications are accessible from even the most modest cockpits (hands-free mobile phones, navigation assistance, security trackers, DVD players and even internet connectivity). Copper has opened up a new window onto the world. As a professional copper alloy provider, Nexteck Technology spares no effort to provide competitive copper products to customers.

In the future, it is likely we will have an autopilot system driven by accelerometers, combined with actuators that will control driving, speed and braking. 360° radar and cameras will keep a constant eye on traffic and the vehicle’s position. Connecting the myriad of connectors, sensors, mini-computers and advanced telecommunications systems, nestling under the bonnet of our smart cars, it will be copper wires that will carry the key power and data signals that will deliver all the above benefits.

Attend exhibitions, focus on industry devolpment trend and new technology,Nexteck Technology Limited keeps pace with the times ,exploring and innovating so as to achieving continuous development.

TAG: electrothermal alloys copper alloys