The life of copper is infinite and has no end phase. Once mined, it can be recycled over and over with no loss of properties. As such, copper is a sustainable material that is pivotal to building the circular economy. Responsible mining and successful recycling help make copper sustainable and resource-efficient.

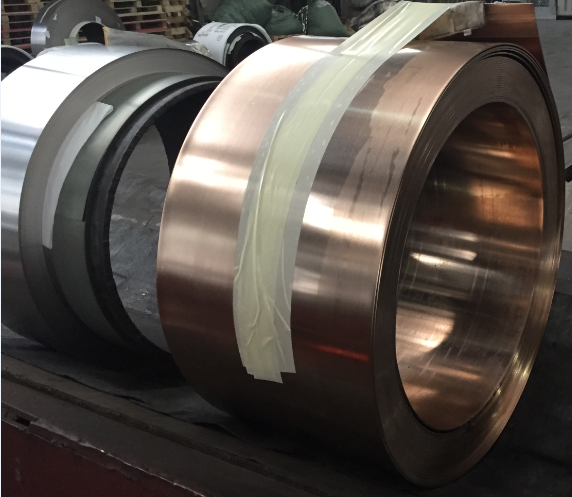

Copper ore used in the EU is mainly imported from Chile, Peru, Australia and the USA, though there is also some production in Europe, including Finland, Poland, Spain and Sweden. Copper mining provides many valuable by-products that can be used in advanced material applications, including cobalt, molybdenum, rhenium, selenium, tellurium and rare earth elements, as well as silver, tungsten, gold, lead and zinc. Copper is the metal of the energy transition, powering renewable energy systems and green technologies. Nexteck Technology provide various metal alloys, such include copper alloys and pure coppers.

Renewable energy systems use up to 12 times more copper than conventional power systems. Copper also typically improves energy efficiency. One tonne of copper used in rotating machines—such as an electric motor or a wind turbine—saves 7,500 tonnes of CO2 emissions over its lifetime.

Copper consumption is predicted to rise more than 40% by 2035. Partly driven by green technologies—like solar and wind power, and electric vehicles—additional demand will be met through mining and recycling. Copper can be recycled repeatedly without any loss of performance, and recycling requires up to 85% less energy than primary production. Globally, this saves 40 million tonnes of CO2 annually.

Europe already leads the world when it comes to copper recycling, with nearly 50% of its copper demand currently met by recycled material. The industry is now working to go even further. The copper industry is at the forefront of industries committed to reducing the environmental impact of its operations. Today, one third of the energy consumption of modern European copper manufacturing is used to operate environmental protection measures. Nexteck Technology also runs copper alloy recycle business.

In response to requests from end-users and regulators—along with the industry’s own sustainable development goals, research and analysis—the copper industry has conducted detailed copper life cycle assessments (LCA) on the production of copper metal, and the leading semi-finished copper products (sheet, tube and wire). Click the link below to explore the Copper Life Cycle Analysis.

Attend exhibitions, focus on industry devolpment trend and new technology,Nexteck Technology Limited keeps pace with the times ,exploring and innovating so as to achieving continuous development.

TAG: copper pure copper