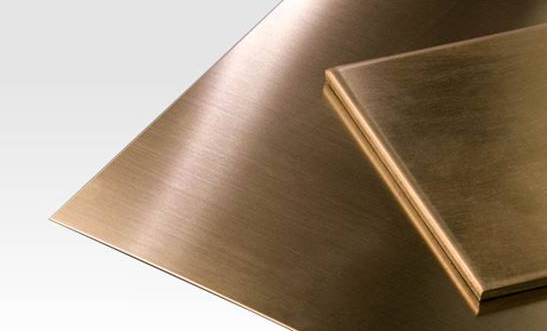

Cu–Ti alloys are now receiving a great deal of attention as ultra-high strength conductive materials for applications such as conductive springs, interconnections etc. essentially displacing the conventional Cu–Be alloy series. A lot of electrically conductive springs of thin plate type are made of an age-hardened copper titanium alloy because of its excellent mechanical strength and electrical conductivity. Such spring sheets are usually produced by a process which includes preparing a copper titanium melt, casting it, hot working the cast copper titanium, subjecting the hot-worked copper titanium to alternate annealing and cold working to final shape, subjecting the copper titanium to solution heat treatment, and age-hardening it after cold working, if required. Its solution heat-treated structure has, however, an average crystal grain size of at least 40 microns and even up to 100 microns.

This move away from Cu–Be has been catalyzed to a large extent by the full recognition of serious health hazards associated with the Be-based metallurgy in production. It is likely that the precipitation hardened Cu–Ti alloys will rise to prominence as a commercial alternative in a myriad of applications over the next decade. Nexteck's CuTi alloy are broadly utilized in conductive springs, interconnections and more.

The age hardening of copper–titanium (Cu–Ti) alloys containing approximately 1–5 wt.% Ti (1–6 at.% Ti) has been known since the 1930s. The mechanical and physical properties were found to be comparable to the widely used copper–beryllium (Cu–Be) alloys with better high temperature strength and superior stress relaxation behavior. The electrical conductivity of the aged alloys, however, falls somewhat below that of the Cu–Be alloys.

The age-hardened copper titanium alloy has been developed as an inexpensive substitute for a well-known age-hardened copper beryllium alloy. The conventional age-hardened copper titanium alloy is, however, not satisfactory, and required to be improved, in view of mechanical properties such as formability, fatigue strength, elongation and yield strength. Moreover, it has the drawback of having different properties in the rolling direction and in a direction perpendicular thereto.

Attending exhibitions, focusing on industry devolpment trend and new technologies,Nexteck Technology Limited keeps pace with the times ,exploring and innovating so as to achievingcontinous development.

TAG: Copper-Titanium Alloys Cu-Ti alloys