Beryllium-copper, available in sheet, strip, foil, wire, rod, tube and forgings, is the hardest (HV 100-420) and strongest (tensile strength 410-1400 N/mm2) of any copper alloy in the fully heat treated and cold worked condition.

It is similar in mechanical properties to many high strength steels but, compared to steels, it has better corrosion resistance (approximately equivalent to nickel-silvers), higher electrical conductivity (16-65% IACS) and higher thermal conductivity (210W/moC). It is also non-sparking and non-magnetic. Beryllium-copper should only be specified where its unique combination of properties can be fully exploited.

The anti-galling, strength and good corrosion resistance led to the widespread use of beryllium-copper for non-sparking tools in the mining, gas and petrochemical industries.

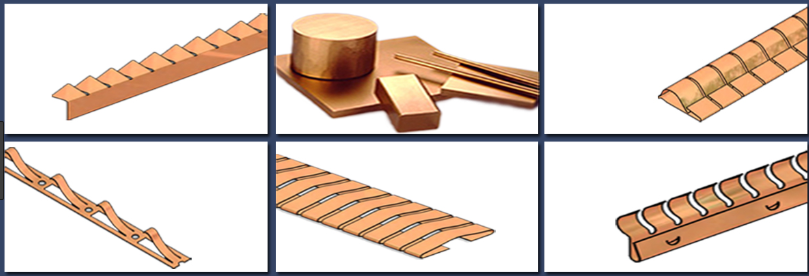

Because of the excellent fatigue resistance, beryllium-copper is widely used for springs, pressure responsive diaphragms, flexible bellows, connectors, contacts and relays, which are all subject to cyclical loading.

Smaller component size has become the main design criterion in the telecommunications and computer electronics markets. Companies are constantly looking for ways to reduce the size and weight of their products, such as mobile phones, tablets, lap-tops, iPads, without sacrificing performance.

The unique combination of strength, electrical and thermal conductivity of beryllium-copper make it an ideal choice for miniaturised components in the above applications.

The inhalation of beryllium in a finely divided form can cause a serious lung condition in some individuals. Precautions must therefore be taken in melting, casting, machining and welding of beryllium-copper. However, in service beryllium-copper is perfectly safe to handle and use.

Attending exhibitions, focusing on industry devolpment trend and new technologies,Nexteck Technology Limited keeps pace with the times ,exploring and innovating so as to achievingcontinous development.

TAG: beryllium-copper