Copper, the most common used metal, has outstanding corrosion resistant ability in the atmosphere as well as fresh water. In seawater, however, has superior corrosion resistance. To prevent damage by wood-boring insects and worms such as the teredo, and reduce coverage of weed and molluscs, copper cladding of wooden-hulled warships, introduced by the Royal Navy in the 18th century.

A brass alternatives for copper was developed in the 19th century, consisting of around 60% copper and 40% zinc. It was called Muntz Metal and cheaper than copper, which could be hot rolled into thin sheets and utilized on a sailing boat cladding the wooden hull at the beginning.

Nickel added to copper, namely Nickel Copper Alloy, improves the copper's strength and durability as well as the resistance to corrosion and erosion in natural waters, including seawater, brackish and treated water. These copper alloys also show excellent mechanical properties, including resistance to corrosion fatigue and stress-corrosion cracking.

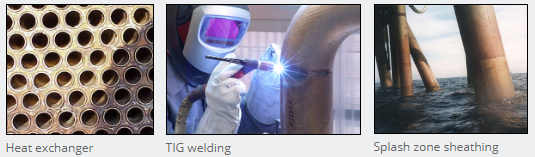

Copper alloy is an ideal material for use in marine and saltwater environments for commercial and naval shipping, desalination plants, heat exchangers and equipment, sea water and hydraulic pipelines, seawater intake screens, ship and boat hulls, offshore renewable, oil rigs and platforms, fish farming cages and more.

Attend exhibitions, focus on industry devolpment trend and new technology,Nexteck Technology Limited keeps pace with the times ,exploring and innovating so as to achieving continuous development.

TAG: copper alloy nickel copper alloy